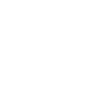

PiGateway is the bridge between the shop floor production and business level operations to bring transparency to your production.

- Whether it is plastic injection moulding, automation or peripheral devices, PiGateway enables you collect data from your existing production equipment.

- PiGateway supports a variety of functions and is not just a protocol converter.

- As a consistent solution, the connection to the business level systems can be implemented according to the customer requirements.

- Long-term corporate success in the digital environment depends on consistent and reliable data acquisition.

- bfa ensures that all data is available to our customers.

Configurable

With horizontal and vertical connectivity, transparent production becomes a reality. PiGateway ensures this through its flexible configuration.

Machine interface – PiGateway

On the shop floor level (machine connection), many bfa standard configurations are available for the various machine types, such as injection moulding machines or automation systems that are equipped with PLC controllers. Based on the standard configuration, the customer-specific data is configured during the project implementation. The data acquisition can be flexibly configured for the entire data set or differentiated for selected groups. Event-based data acquisition is often used in traceability applications. PiGateway guarantees the high-performance and consistent data acquisition of large amounts of data.

PiGateway – business systems

Due to the configuration abilities of PiGateway, the data collected from the shop floor can be processed and is transferred to the business level system. This flexibility is required because the degree of standardization of the interfaces to business systems is lower than that of the machine interfaces, so in some scenarios a customised connection is necessary. Of course, standards such as OPC UA are used whenever possible. With classic gateway systems, the address name must often be taken over by the machine control system. With PiGateway the address names can be freely configured for the business system.

Scalable

No matter the type of machine, the scalability of the software and hardware opens all possibilities.

PiGateway Server – one type of hardware for all machines

When connecting several machines, i.e. one server for all machines, the central solution is available. This solution has the advantage that the administration of a central system is easy. The disadvantage is that if the PiGateway server is down, the data acquisition of all machines is interrupted.

PiGateway Server – single piece of hardware per machine or for a group of machines

With this solution the administration effort is increased. On the other hand, the availability is high and a failure (e.g. during maintenance) only affects the data acquisition from one machine or the group.

Scalability of the software

PiGateway is scalable in that the data loggers and the communication drivers (e.g. Siemens S7 or EM15/63/77). This configuration is used for extensive installations with many machines and/or large amounts of data per machine.

Smart

PiGateway is not only a protocol converter! The complex processes can be easily implemented by our «Logic Engine» using SQL scripts or C# code.

PiGateway Co-ordination

PiGateway can also take on a coordinating role by monitoring and controlling communication between the shopfloor level and business level. This function is used, for example, for the central storage and release of machine programs or order handling between the ERP and the machines.

If production-related functions cannot be covered by the business level system, the appropriate module can be selected from our modular MES PiSolutions. As an example, we have a module for the dataset handling of injection moulding machines. Normally, the dataset handling is not covered by business level systems.

Reliable

The temporary storage of machine data in the PiGateway server increases the availability of the entire system. A temporary shutdown of the business level system does not lead to a loss of data.

PiGateway as data storage

PiGateway can be equipped with a database for storing historical data. The amount of data to be stored per machine as well as the duration of the temporary storage defines the size of the storage space of the PiGateway server. The buffering of data is useful for maintenance of the business level system. On the other hand, it can be used as a data buffer if the machine data cannot be taken over by the system.

Maintainable

Digitalization brings a higher complexity in the maintenance of the IT infrastructure. We think ahead and the Life Cycle Management of our products is guaranteed.

PiGateway supports maintenance

PiGateway is the link between the shop floor level and the business level. For maintenance PiGateway has a coordinating role. Special attention must be paid to maintenance work that has an influence on the interfaces. Software updates on the machine level always have an influence on the communication. With the bfa Life Cycle Management, the communication blocks and libraries can be updated as required and the long-term availability of PiGateway is guaranteed.

Independent

As a software company independent of machine suppliers and control manufacturers, we can provide a solution which is future proof should the customer migrate to different suppliers.

bfa as a independent company

Thanks to our independence, we have been able to build up know-how in different industries since we were founded. With this knowledge we can support our customers to a fully connected production.

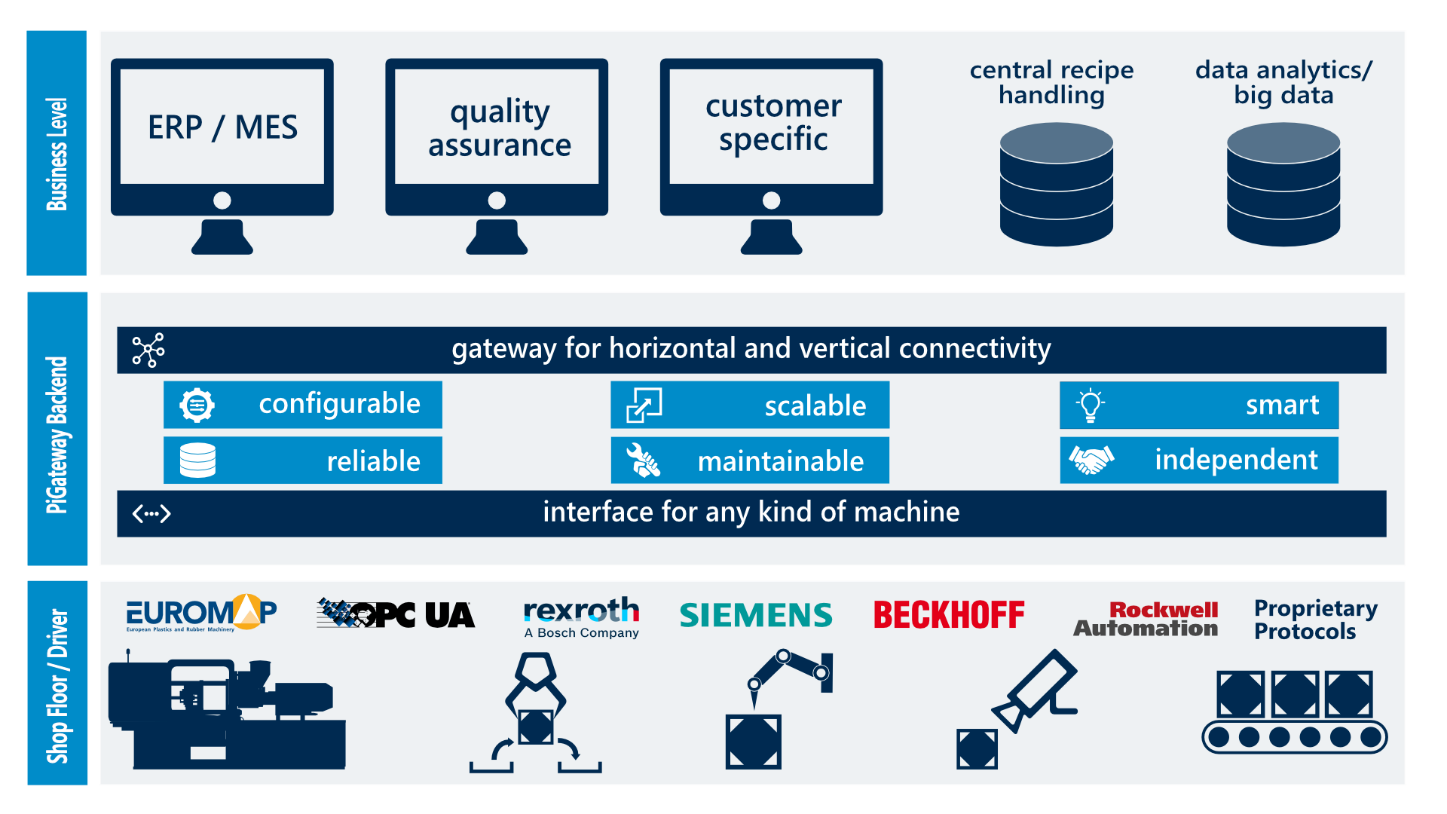

PiGateway Core

As an alternative to installing the PiGateway software on a Windows server infrastructure, we also offer our customers installation on an edge computer from Bosch Rexroth. With this solution the data load is distributed and increased availability can be guaranteed.

Success Story

For several customers in South Korea we have successfully provided our systems with the PiGateway solution from bfa. In addition to data acquisition from injection moulding machines, peripheral devices such as vision systems, cooling units and dryers all require data to be transferred to the business level system. Vertical and horizontal connectivity enables the entire machine inventory to be networked. With PiGateway, our customers receive transparency of their production in real time.

PiGateway – procedure

1.

An extension of the PiGateway standard function specification coupled with the customer specific requirements, is based on the machinery being connected to the business level system.

2.

System configuration and realisation of the customer specific requirements.

3.

System installation on an internal test system at bfa is where the FAT (Factory Acceptance Test) will take place.

4.

System installation at the customer site can be done via remote or on-site as well as performing the SAT (Site Acceptance Test).

We are there for you.

Please send us an email or call us on +41 44 806 64 64.